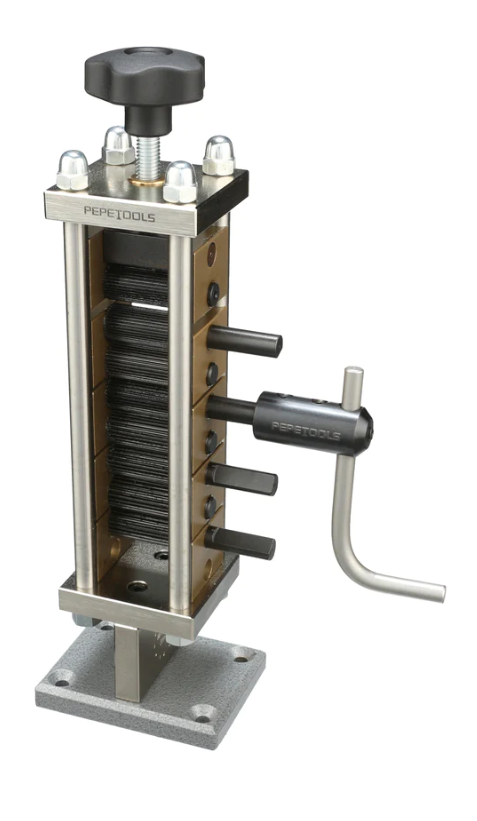

As promised, a description of the router/engraver.

The above picture was an advertisement for Comgrove ROBO Router/Engraver. They are no longer made. If you do a search on "tabletop router/engraver", you'll see several types and sizes of machines.

Now on with ROBO (have no idea why they called it that). I ordered it off of Amazon.

It basically came as a kit. All the parts laid out. The screw gun shows relative size of router/engraver.

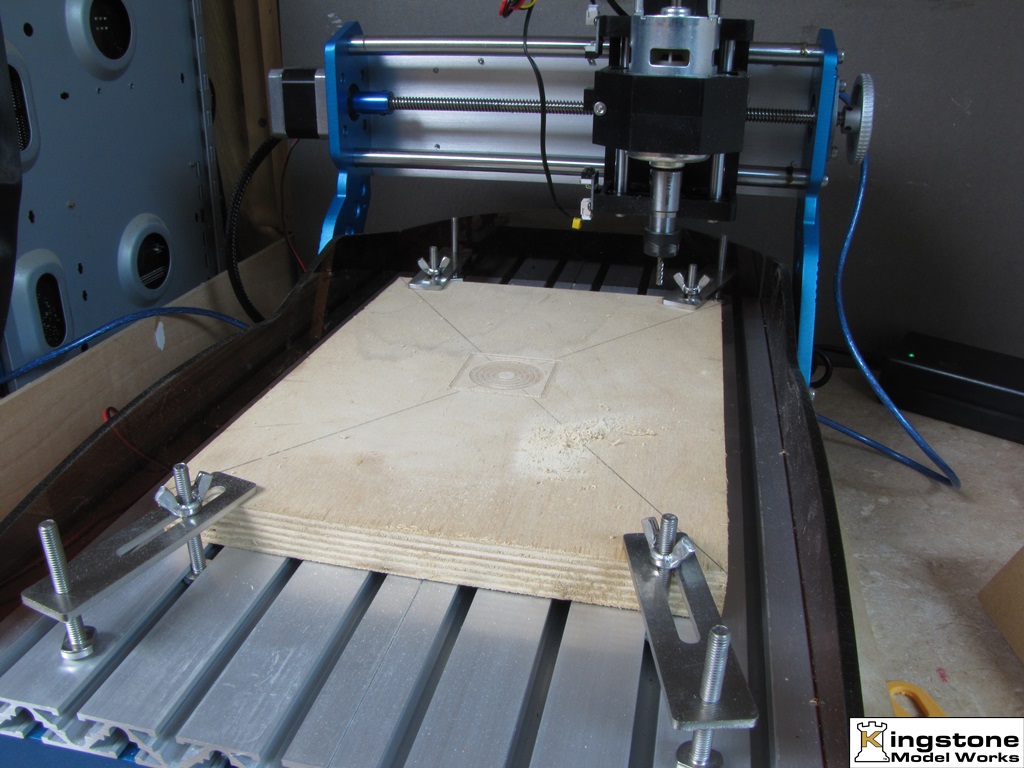

The machine completely assembled.

The back of the machine showing the offline controller's mounting spot.

The off line controller showing the control buttons.

The SDHC slot.

First test cut. Several circles surrounded by square.

This basically describes the machine I bought. When this one electrically dies, I plan on getting another router/engraver. I'm looking at getting a Genmitsu 4040-PRO. It has a larger work envelop than the ROBO at 15'7" X 15.7" X 3.1". Here's a link to Amazon on what it looks like and price.

https://tinyurl.com/rjczpenn

I have actually two tabletop CNC machines, the ROBO and a Sherline CNC. Both are very useful tools since you can work almost any kind of material used in model railroading or structure builds. I find 3D printers limited in what they can do because you can only add stock, not remove stock as you can with a CNC or any machine tool. I believe 3D printers are great if you want to make a master for casting something in resin or even plaster. Even though I have a 3D printer I found learning 360 Fusion or any other 3D CAD program as being very time consuming. And if you don't use the program enough you forget how to use it. Also having grown up in the machine tool industry where I learned how to operate the larger machines in making parts, learning to use the tabletop machines was easy for me.

Next post I'll go into what it took to make those windows.

To be continued.

Bernd

The above picture was an advertisement for Comgrove ROBO Router/Engraver. They are no longer made. If you do a search on "tabletop router/engraver", you'll see several types and sizes of machines.

Now on with ROBO (have no idea why they called it that). I ordered it off of Amazon.

It basically came as a kit. All the parts laid out. The screw gun shows relative size of router/engraver.

The machine completely assembled.

The back of the machine showing the offline controller's mounting spot.

The off line controller showing the control buttons.

The SDHC slot.

First test cut. Several circles surrounded by square.

This basically describes the machine I bought. When this one electrically dies, I plan on getting another router/engraver. I'm looking at getting a Genmitsu 4040-PRO. It has a larger work envelop than the ROBO at 15'7" X 15.7" X 3.1". Here's a link to Amazon on what it looks like and price.

https://tinyurl.com/rjczpenn

I have actually two tabletop CNC machines, the ROBO and a Sherline CNC. Both are very useful tools since you can work almost any kind of material used in model railroading or structure builds. I find 3D printers limited in what they can do because you can only add stock, not remove stock as you can with a CNC or any machine tool. I believe 3D printers are great if you want to make a master for casting something in resin or even plaster. Even though I have a 3D printer I found learning 360 Fusion or any other 3D CAD program as being very time consuming. And if you don't use the program enough you forget how to use it. Also having grown up in the machine tool industry where I learned how to operate the larger machines in making parts, learning to use the tabletop machines was easy for me.

Next post I'll go into what it took to make those windows.

To be continued.

Bernd